Extrusion Lines

Best Sioplas Line Manufacturers in India

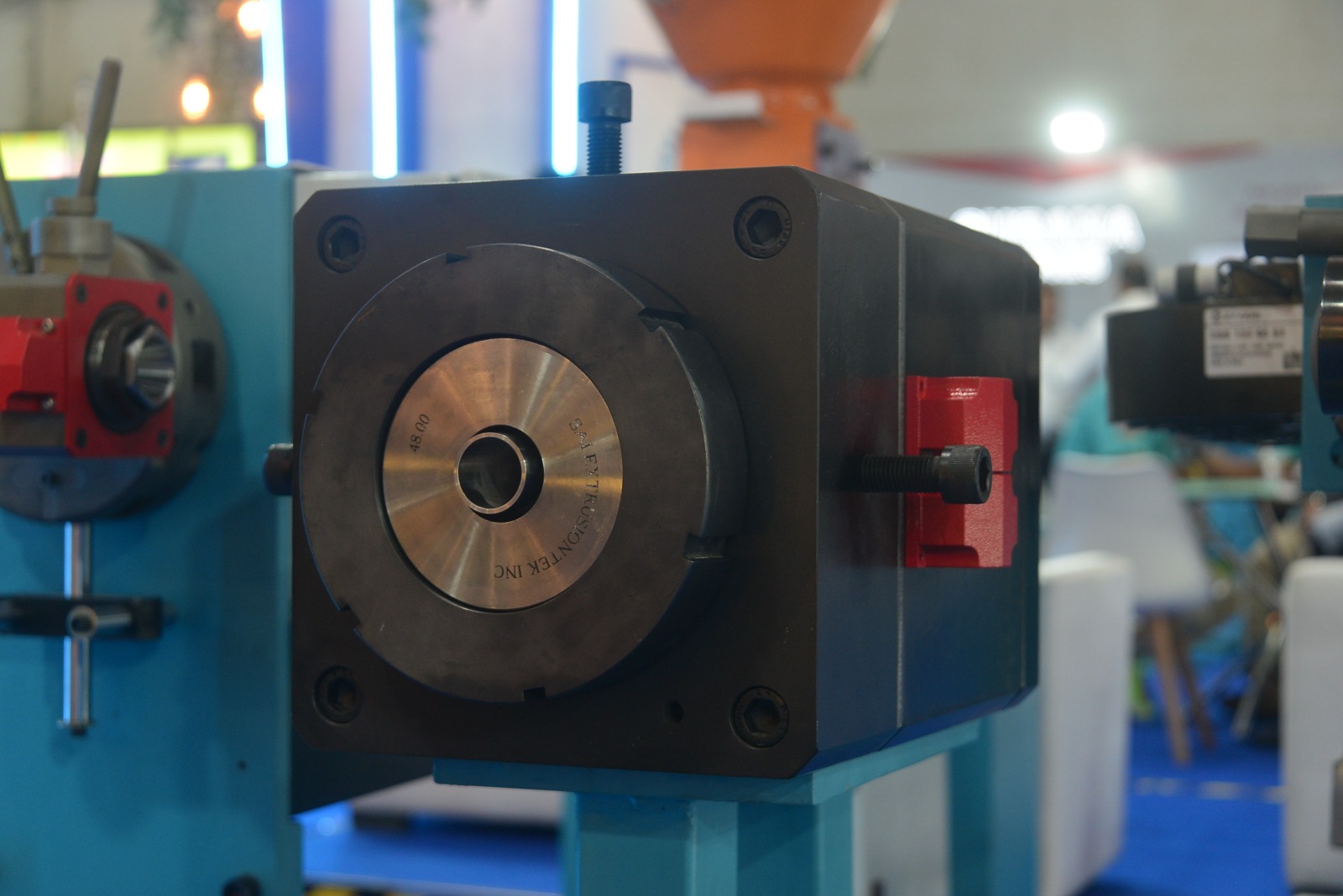

At Sai Extrusiontek Inc., we manufacture the best extruders and industrial extrusion lines for the cable and wire industry. Our high-performance systems ensure consistent insulation quality, precise diameters, and superior material adhesion, ideal for power, communication, and specialty cables.

As the best Sioplas line manufacturer in India, we offer advanced Sioplas extrusion lines designed for the efficient production of XLPE (cross-linked polyethylene) insulated cables using the silane crosslinking method. Our Sioplas lines combine a silane-grafted polyethylene compound with a catalyst masterbatch, delivering high-quality insulation and sheathing for low and medium voltage cables. Trusted by cable manufacturers across India, our extrusion lines are reliable, energy-efficient, and cost-effective, ensuring consistent performance and superior insulation quality. By choosing us, you get the expertise of the best Sioplas line manufacturer in India, committed to providing solutions that meet modern cable manufacturing demands.

Our plastic and rubber extruders deliver minimal waste, energy efficiency, and reliable operation. With advanced PLC controls, precision screw and barrel designs, and in-line monitoring, they guarantee uniform insulation thickness and flawless cable coating.

From single-screw extruders to co-extrusion systems for multi-layer cables, we provide customizable solutions thoroughly tested for smooth installation, reliable operation, and maximum uptime.

Partnering with Sai Extrusiontek Inc. gives you access to top extrusion technology, along with full design, commissioning, training, and after-sales support to maximize productivity and product quality.

Single-Screw Extrusion Lines

Twin-Screw Extrusion Lines

Co-Extrusion Lines

PVC / Rubber Extrusion Lines

High-Speed Cable Extrusion Lines

MVCC Extrusion Lines

HDPE / PE Cable Extrusion Lines

Foam Extrusion Lines

Multi-Layer Co-Extrusion Lines

Braiding & Jacketing Integration Lines

Micro / Thin Film Extrusion Lines

Sioplas Extrusion Lines

Single-screw extrusion lines are widely used for standard insulation and sheathing of cables. They deliver consistent diameters, reliable insulation quality, and smooth operation, making them ideal for general wire and cable production.

Twin-screw extrusion lines provide excellent mixing and compounding, especially when processing filled polymers, additives, or masterbatches. These systems ensure uniform insulation quality and superior coating performance for demanding applications.

Co-extrusion lines are designed for producing multi-layer cables. By combining different polymers in a single process, they improve mechanical strength, electrical properties, and thermal resistance while ensuring strong adhesion between layers.

PVC and rubber extrusion lines are engineered for high-quality insulation and sheathing using PVC, PE, or rubber compounds. They guarantee precise wall thickness, smooth surface finishes, and energy-efficient performance.

High-speed extrusion lines are built for large-scale cable production. With advanced PLC controls and in-line monitoring, they ensure flawless insulation and uniform coating even at maximum production speeds.

MVCC (Multi-Layer Vacuum Calibration) extrusion lines offer precision and consistency in cable manufacturing. With vacuum calibration tanks and advanced control systems, they ensure exact diameters, uniform insulation thickness, and top-quality jacketing.

HDPE and PE extrusion lines are designed for telecom and power cables. They maintain accurate wall thickness, excellent adhesion, and smooth surfaces, making them reliable for high-performance applications.

Foam extrusion lines are used to produce lightweight insulation layers. These systems reduce material consumption while maintaining excellent dielectric properties, making them cost-effective and efficient.

Multi-layer co-extrusion lines allow the production of advanced cables with multiple protective layers. They enhance durability, thermal stability, and overall electrical performance in specialty and high-voltage cables.

These lines combine extrusion with braiding or stranding processes, enabling direct jacketing over braided or armored cables. This integration reduces handling, increases production speed, and ensures perfect coating alignment.

Micro and thin-film extrusion lines are developed for fine cables requiring very thin insulation layers. With precise control of thickness and tension, they are widely used in fiber optic, medical, and instrumentation cables.

As the best Sioplas line manufacturer in India, we offer advanced Sioplas extrusion lines designed for the efficient production of XLPE (cross-linked polyethylene) insulated cables using the silane crosslinking method. Our Sioplas lines combine a silane-grafted polyethylene compound with a catalyst masterbatch, delivering high-quality insulation and sheathing for low and medium voltage cables. Trusted by cable manufacturers across India, our extrusion lines are reliable, energy-efficient, and cost-effective, ensuring consistent performance and superior insulation quality. By choosing us, you get the expertise of the best Sioplas line manufacturer in India, committed to providing solutions that meet modern cable manufacturing demands.

Key Features:

- High Performance Insulation: Produces XLPE with excellent electrical, thermal, and mechanical properties.

- Cost-Effective Technology: Lower investment and operating costs compared to peroxide or CV (continuous vulcanization) methods.

- Energy Efficient: Eliminates the need for high-pressure steam curing.

- Flexibility: Suitable for both insulation and sheathing applications.

- Consistent Quality: Ensures uniform mixing and smooth extrusion with precision control systems.

Applications:

- Low Voltage Power Cables

- Medium Voltage Power Cables

- Communication and Special Cables

Our Sioplas extrusion lines provide reliability, efficiency, and long-term performance, making them the ideal solution for modern cable manufacturers.